An undocumented modifications on Wisdom Venture oil tanker resulted in burns to three crew members, according to the Australian Transport Safety Bureau (ATSB).

What happened

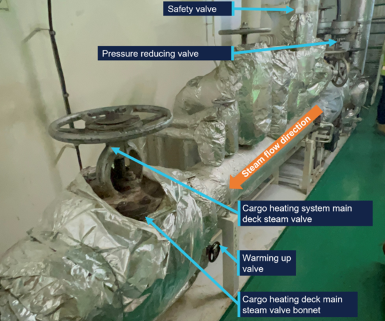

On 6 May 2025, the oil tanker Wisdom Venture was drifting off Sydney, New South Wales, when the engineering team commenced maintenance on the main deck steam valve for the cargo heating system. The valve had been leaking from the bonnet joint gasket.

Following isolation of the system, the team removed the valve bonnet. During this process, residual hot condensate was suddenly released, resulting in burn injuries to 3 crew members.

First aid was administered on board, and the injured personnel were subsequently evacuated to shore for medical treatment.

What the ATSB found

The ATSB found that prior to commencing maintenance work on the cargo heating system main deck steam valve, the crew did not allow adequate time for the steam system to cool. In addition, the verification system to ensure that the steam line was fully depressurised was not used. This was most likely due to the time pressures to reintroduce heating to the main engine fuel system.

The ATSB also found that a drain line in the warm-up bypass line had been permanently modified without formal approval or documentation. This change was not incorporated into a risk assessment and no formal review was conducted. This undocumented change likely introduced a system vulnerability that undermined the effectiveness of the steam system isolation.

Additionally, the modification was not identified in the chief engineer’s handover process, leaving the incoming engineering team unaware of the altered configuration and associated risks. It was also not identified during routine technical inspections or superintendent riding visits. This resulted in the ship manager’s management of change process not being applied.

What has been done as a result

Following the incident, the ship manager advised that the drain line on Wisdom Venture has been returned to its original design configuration. A fleetwide campaign has also been initiated to identify any unauthorised modifications to shipboard piping systems. Where such modifications are identified, internal investigations will be conducted.

To raise awareness of the risks associated with undocumented engineering changes, the incident will be included in pre-joining briefings for senior engineering staff and discussed during crew seminars. Ship staff will also be reminded that all modifications must be undertaken in consultation with the office and in accordance with the company’s management of change process.

Finally, to improve oversight and strengthen management of change procedural compliance, the superintendent’s inspection report will be amended to include verification of any shipboard system modifications not reflected in the ship’s design drawings. These actions are intended to ensure that future modifications to critical systems are properly assessed, documented, and communicated.

Safety message

The incident highlights the critical importance of adhering to established safety and management of change procedures. Where changes are to be made to a system, these need to be recorded and the processes to identify the risks need to be followed to ensure there are no unintended consequences.

In addition, operators are reminded that maintenance involving steam systems must allow sufficient cooling time and include visual confirmation of isolation. Reliance solely on pressure indicators is not sufficient to ensure safe working conditions.

Read the full final report: ATSB-Final report MO-2025-004-Wisdom Venture